The Introduction to QFN Package

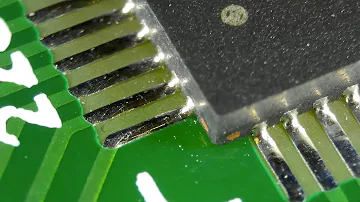

SMD Soldering - QFN Package

Topics Covered in This Article: |

Ⅰ. What is a QFN Package? |

Ⅰ. What is a QFN Package?

The Quad Flat No-leads (QFN) package is a type of surface-mount technology (SMT) that has become a cornerstone of modern electronics due to its compact size and excellent performance. Unlike older packages like the Quad Flat Package (QFP) or Plastic Leaded Chip Carrier (PLCC), the QFN has no external leads (or "gull wings"). Instead, it features metal pads, known as "lands," on the underside of the package for electrical connection.

The four sides of the package are equipped with these electrode contacts. This leadless design results in a smaller mounting area and a lower profile compared to QFP. QFN packages are typically made from ceramic or plastic. Plastic QFNs, often built on a glass-epoxy substrate, are a cost-effective solution with common electrode contact pitches of 0.65mm and 0.5mm. The term QFN was originally defined by the Japan Electronics and Information Technology Industries Association (JEITA).

Ⅱ. Key Features and Advantages

The QFN package is distinguished by a large exposed pad in the center of its bottom surface. This pad serves as a thermal connection, providing a direct path for heat to dissipate from the chip to the printed circuit board (PCB). The short conductive path between the internal die and the external pads results in very low self-inductance and wiring resistance, granting it superior electrical performance, especially for high-frequency applications.

These characteristics—small size, light weight, and outstanding electrical and thermal properties—make QFN packages ideal for any application where size and performance are critical. For instance, a 32-pin QFN (5x5mm) can reduce the footprint by 84% and thickness by 80% compared to a traditional 28-pin PLCC. This miniaturization is a key reason for its rapid adoption in mobile phones, digital cameras, automotive electronics, and IoT devices. The global QFN package market was valued at approximately USD 278 million in 2024 and is projected to continue its steady growth, driven by these high-demand sectors.

Ⅲ. PCB Design for QFN Packages

Proper PCB design is critical for leveraging the full potential of QFN packages. While early designs often referenced the IPC-SM-782 standard, the more modern IPC-7351 series is now the primary industry guideline for land pattern design. Key design considerations include the peripheral pads, the central thermal pad, and the solder mask.

Thermal Pad and Via Design

To effectively transfer heat, the PCB must have a corresponding thermal pad and thermal vias directly beneath the QFN's exposed pad. The vias create a pathway for heat to dissipate into the ground planes of the PCB. A typical via array pattern uses a 1.0mm to 1.2mm pitch with via diameters of 0.3mm to 0.33mm. Vias can be tented, filled, or left as open through-holes, each method offering trade-offs in voiding and solder flow.

Stencil Design

Stencil design is crucial for achieving reliable solder joints. For the central thermal pad, it is recommended to use an array of smaller openings (a "windowpane" design) instead of one large opening. This approach helps reduce solder voiding by allowing gases to escape during reflow. A solder paste coverage of 50% to 80% is typical. For peripheral pads, the stencil aperture is usually designed to be slightly smaller than the pad to prevent solder bridging, especially for fine-pitch (≤0.5mm) components.

Ⅳ. The Evolution of QFN Technology

The basic QFN package has evolved into several variants to meet increasingly demanding application requirements:

WQFN (Very-thin QFN): An even thinner version of the package, often with a finer pitch (e.g., 0.35mm), allowing for a higher I/O count in a smaller area.

FC-QFN (Flip-Chip QFN): This variant uses flip-chip interconnects, which dramatically shorten the signal path (<100 µm). This is ideal for high-frequency applications like millimeter-wave (mmWave) radar and 5G antennas.

SiP-QFN (System-in-Package QFN): Integrates multiple dies and/or passive components into a single QFN package, creating a complete subsystem in a tiny form factor.

Wettable Flank QFN: Features a special plating on the side edges of the pads. This creates a visible solder fillet after reflow, which is crucial for automated optical inspection (AOI) and is often a requirement in the automotive industry.

Ⅴ. Solder Joint Inspection and Rework

Inspection

Inspecting QFN solder joints is challenging because the primary connections are hidden beneath the package. While Automated Optical Inspection (AOI) can check for peripheral issues like solder bridging, it cannot see the crucial joints on the pads. This is where Automated X-ray Inspection (AXI) becomes essential. AXI can verify the integrity of the solder joints on the I/O pads and, critically, assess the level of voiding in the central thermal pad. The development of wettable flank QFNs has also been a major step forward, as it allows standard AOI systems to verify soldering on the package's perimeter.

Rework

Reworking QFN components is a delicate process, similar to that for Ball Grid Arrays (BGAs). Defects like bridges, opens, or excessive voiding require the component to be removed. This is typically done using specialized hot-air rework stations that can apply focused heat to the component without damaging the surrounding board. Re-applying solder paste for a new component is the most challenging step and can be done by mini-stenciling the PCB, dotting paste onto the pads, or pre-bumping the component itself. The process requires skilled technicians and precise equipment to control heat and prevent blowing the lightweight component off the board.

Note: This article was updated in October 2025 to reflect the latest industry standards, market trends, and technological advancements in QFN packaging. The original version was published in 2021. Key updates include the correction of "repairment" to "rework," the inclusion of the modern IPC-7351 standard, and the addition of new QFN variants like FC-QFN and Wettable Flank QFN.

1. How to solder the QFN package?

1. Air gun 230° 2. The time is less than 1 minute and can be welded multiple times 3. Slowly heat, from far to near, blowing vertically 4. Apply the solder paste between the chip and the board in advance, the amount needs to be tried by yourself 5. After the solder paste is melted, shake the chip with tweezers to make sure that each foot is stuck to the pad and not stuck to other feet. Under normal circumstances, use tweezers to slightly move the chip and release it, and the chip will return to its original position, otherwise there will be too much or too little solder paste.

2. What is the full name of the QFN package?

QFN = Quad Flat Non-leaded, a quad flat non-leaded package.

3. What is the difference between DFN package and QFN package?

First, The characteristics of the two are different: 1. Features of DFN package: DFN package has high flexibility. 2. Features of QFN package: QFN package peripheral pin pad design; middle thermal pad and via hole design; consideration of PCB solder mask structure. Second, The two are essentially different: 1. The essence of DFN packaging: DFN packaging is a kind of latest electronic packaging technology, using advanced double-sided or quad flat lead-free packaging.

Discovering New and Advanced Methodology for Determining the Dynamic Characterization of Wide Bandgap DevicesSaumitra Jagdale15 March 20242382

Discovering New and Advanced Methodology for Determining the Dynamic Characterization of Wide Bandgap DevicesSaumitra Jagdale15 March 20242382For a long era, silicon has stood out as the primary material for fabricating electronic devices due to its affordability, moderate efficiency, and performance capabilities. Despite its widespread use, silicon faces several limitations that render it unsuitable for applications involving high power and elevated temperatures. As technological advancements continue and the industry demands enhanced efficiency from devices, these limitations become increasingly vivid. In the quest for electronic devices that are more potent, efficient, and compact, wide bandgap materials are emerging as a dominant player. Their superiority over silicon in crucial aspects such as efficiency, higher junction temperatures, power density, thinner drift regions, and faster switching speeds positions them as the preferred materials for the future of power electronics.

Read More A Comprehensive Guide to FPGA Development BoardsUTMEL11 September 202510546

A Comprehensive Guide to FPGA Development BoardsUTMEL11 September 202510546This comprehensive guide will take you on a journey through the fascinating world of FPGA development boards. We’ll explore what they are, how they differ from microcontrollers, and most importantly, how to choose the perfect board for your needs. Whether you’re a seasoned engineer or a curious hobbyist, prepare to unlock new possibilities in hardware design and accelerate your projects. We’ll cover everything from budget-friendly options to specialized boards for image processing, delve into popular learning paths, and even provide insights into essential software like Vivado. By the end of this article, you’ll have a clear roadmap to navigate the FPGA landscape and make informed decisions for your next groundbreaking endeavor.

Read More Applications of FPGAs in Artificial Intelligence: A Comprehensive GuideUTMEL29 August 20252672

Applications of FPGAs in Artificial Intelligence: A Comprehensive GuideUTMEL29 August 20252672This comprehensive guide explores FPGAs as powerful AI accelerators that offer distinct advantages over traditional GPUs and CPUs. FPGAs provide reconfigurable hardware that can be customized for specific AI workloads, delivering superior energy efficiency, ultra-low latency, and deterministic performance—particularly valuable for edge AI applications. While GPUs excel at parallel processing for training, FPGAs shine in inference tasks through their adaptability and power optimization. The document covers practical implementation challenges, including development complexity and resource constraints, while highlighting solutions like High-Level Synthesis tools and vendor-specific AI development suites from Intel and AMD/Xilinx. Real-world applications span telecommunications, healthcare, autonomous vehicles, and financial services, demonstrating FPGAs' versatility in mission-critical systems requiring real-time processing and minimal power consumption.

Read More 800G Optical Transceivers: The Guide for AI Data CentersUTMEL24 December 20251793

800G Optical Transceivers: The Guide for AI Data CentersUTMEL24 December 20251793The complete guide to 800G Optical Transceiver standards (QSFP-DD vs. OSFP). Overcome supply shortages and scale your AI data center with Utmel Electronic.

Read More Xilinx FPGAs: From Getting Started to Advanced Application DevelopmentUTMEL09 September 20253559

Xilinx FPGAs: From Getting Started to Advanced Application DevelopmentUTMEL09 September 20253559This guide is your comprehensive roadmap to understanding and mastering the world of Xilinx FPGA technology. From selecting your first board to deploying advanced AI applications, we'll cover everything you need to know to unlock the potential of these remarkable devices. The global FPGA market is on a significant growth trajectory, expected to expand from USD 8.37 billion in 2025 to USD 17.53 billion by 2035. This surge is fueled by the relentless demand for high-performance, adaptable computing in everything from 5G networks and data centers to autonomous vehicles and the Internet of Things (IoT). This guide will walk you through the key concepts, tools, and products in the Xilinx ecosystem, ensuring you're well-equipped to be a part of this technological revolution.

Read More

Subscribe to Utmel !

![AT88SC25616C-PU]() AT88SC25616C-PU

AT88SC25616C-PUMicrochip Technology

![FM3164-G]() FM3164-G

FM3164-GCypress Semiconductor Corp

![HCS301-I/P]() HCS301-I/P

HCS301-I/PMicrochip Technology

![L9660TR]() L9660TR

L9660TRSTMicroelectronics

![MOC3062VM]() MOC3062VM

MOC3062VMON Semiconductor

![MOC3020SR2M]() MOC3020SR2M

MOC3020SR2MON Semiconductor

![FGBS3040E1-F085]() FGBS3040E1-F085

FGBS3040E1-F085ON Semiconductor

![ATSHA204-TSU-T]() ATSHA204-TSU-T

ATSHA204-TSU-TMicrochip Technology

![AD8196ACPZ]() AD8196ACPZ

AD8196ACPZAnalog Devices Inc.

![TLE8110EDXUMA1]() TLE8110EDXUMA1

TLE8110EDXUMA1Infineon Technologies